|

|

|

|

|

|

Band Saw Blades Industrial Carbide proudly represents the MK Morse Company and

Simonds International, both long-time, successful manufacturers

of all varieties of bandsaw blades and other cutting tools. All of our bandsaw blades are factory-welded for

guaranteed performance, and lead times are 2-3 work days in most cases. Find below the different kinds of

blades we offer, along with an explanation of what they are designed to do and their features and benefits.

Once you find the kind of blade you need, click on the link and a PDF price sheet will open. Then you can find

the size blade you need along with the price. Contact us to place an

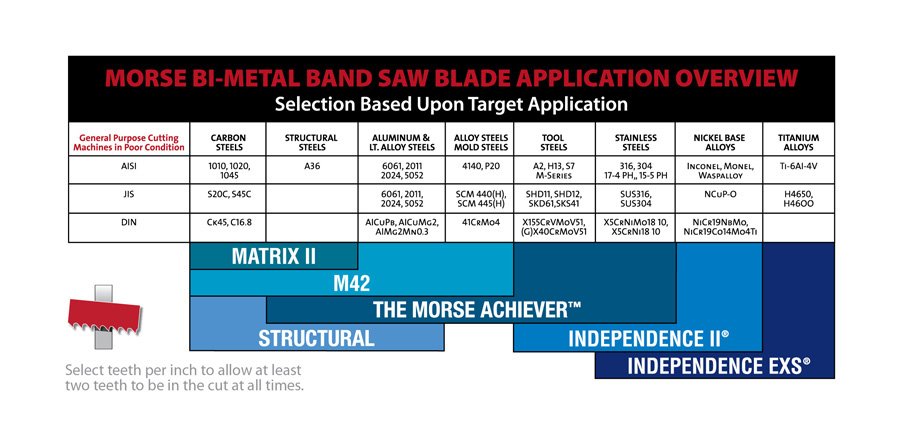

order or to ask for assistance with the blade selection process. The chart at the bottom of this page might help

with your blade choice as well. Don't forget to ask about guaranteed trial orders when we work with you!

Industrial Carbide proudly represents the MK Morse Company and

Simonds International, both long-time, successful manufacturers

of all varieties of bandsaw blades and other cutting tools. All of our bandsaw blades are factory-welded for

guaranteed performance, and lead times are 2-3 work days in most cases. Find below the different kinds of

blades we offer, along with an explanation of what they are designed to do and their features and benefits.

Once you find the kind of blade you need, click on the link and a PDF price sheet will open. Then you can find

the size blade you need along with the price. Contact us to place an

order or to ask for assistance with the blade selection process. The chart at the bottom of this page might help

with your blade choice as well. Don't forget to ask about guaranteed trial orders when we work with you!

- General Purpose (GP) designed for production sawing in alloy and stainless steel applications - Case Hardened (CH) exclusively for chrome plated, case hardened hydraulic shaft specifications, automotive parts, cylinder and bearing manufacturers - Foundry Band (FB) designed for non-ferrous and tough, abrasive wood cutting applications - Exotic (EX) designed for nickle based alloy and stainless steel applications (Inconel, Hastelloy) - Typical users include steel service centers and forging / casting operations - Wear resistant, long life, smooth finish, and fast cutting are primary benefits - CLICK HERE FOR PRICING

- Tougher and more wear-resistant than any other bi-metal blade - Fewer blade changes in a wide range of materials resulting in less downtime - Great on solids - Nickel based alloys, stainless steels, tool steels, and titanium alloys - EXS for large cross section solids and difficult to machine high temperature high strength material - CLICK HERE FOR PRICING

- Production cutting a variety of materials, including 1018, 4140, 4340, tool and stainless steels - Zero degree rake are well suited for production cutting structurals, solids and thin walled pipe - Exceptional tooth durability and fatigue resistance - Ideal for bundle and interrupted cuts with longer life - Increased beam strength to reduce noise from vibration - CLICK HERE FOR PRICING

- Hardened M42 teeth and tool steel fatigue resistant backer - For solids and heavy-walled structurals - Handles hard to machine materials like stainless steel, Inconel, Monel - High wear and heat resistance - Variable pitch teeth can handle a wider range of cross sectional sizes - CLICK HERE FOR PRICING

- For aluminum castings, carbon and structural steel - Tough impact resistance - Handles bundles and stacked pieces - Choose positive rake for solids, zero degree rake angle for tubing / thin wall pipe - CLICK HERE FOR PRICING

- Fatigue Resistant - Hardened Teeth - Good for multiple resharpenings - Can be run at speeds up to 15,000 SFM (surface feet per minute) - See the full Morse line of wood cutting blades here - CLICK HERE FOR PRICING

- Lost cost per cut in pallet dismantling applications - Straight Cuts under heavy feed pressure - Good for multiple resharpenings - Not recommended for blade speeds exceeding 4,000 SFM - See the full Morse line of wood cutting blades here - CLICK HERE FOR PRICING

-  - Submit a quote request for pricing

- Carbon ETS Furniture blades - Tungsten Carbide Grit edge blades (continuous or gulleted) for cutting cast iron, fiberglass, ceramic, composites, graphite, cement, rubber tires, etc. - See the full Morse line of bandsaw blades here - CLICK HERE FOR PRICING  |

|